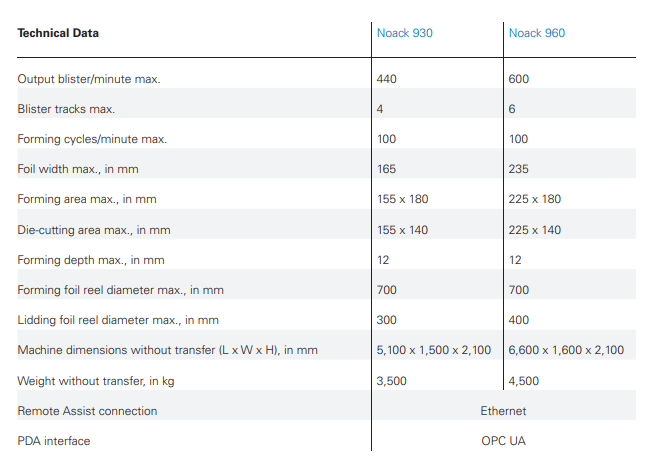

900 Series

900 series from Romaco Noack

The Noack solutions impress with excellent

OEE values. Romaco continuously cuts

customer’s unit packaging costs by delivering optimal value for money. All blister

machines in the Romaco Noack 900 series

can be supplied with either platen or rotary

sealing. A balcony structure ensuring cGMP

compliance together with integrated

Track & Trace and containment solutions

are the hallmarks of this technology. High level of automation with servo and

auto controls ensures precise execution

independent of the operator.

Highlights

• QuickFeed – interchangeable feeding unit

for product changeovers to be completed

within seconds

• QuickAdjust – the automatic station

control system for extremely short run-in

times and highly reliable processes

• QuickChange – complete changeover in

less than 30 minutes thanks to fail-safe

control, easy plug and play, and ergonomic lightweight construction

• QuickTransfer – servo-driven blister

transfer on a vacuum assisted overhead

conveyor

• QuickClean – significantly shorter cleaning times due to easy access, reduced

surfaces and a design without edges and

corners

• QuickAdmin – absolutely reproducible

processes and ergonomic HMI panel with

intuitive visualisation and navigation

• QuickControl – maximum production safety along with Track & Trace, audit trail and

batch records

• QuickConnect – Ready for Remote Assist;

OPC UA interface for production data

acquisition (PDA)